Radiation tolerant cameras

This document was created to assist anyone who needs a new camera for a nuclear application.

Or learn more about parameters in play when choosing a suitable camera. Examples of questions to be answered before a purchase are:

-Is there any radiation in the area where the camera is to be placed?

-What is the radiation level?

-Is a standard camera enough or is a radiation tolerant camera necessary?

–How will the camera be protected from radiation?

-Is the camera for underwater use or use in air?

-How accessible is the camera, how often is it possible to perform service?

-What is the camera going to look at, where is it going to be fixated?

-What resolution is required?

Is there any radiation where the camera is installed?

In environments where nuclear radiation exists, standard cameras have a limited survival time. The reason for that is that nuclear radiation is harmful to the electrical components that are abundant in a modern standard camera. In a nuclear facility, there are two types of radiation that affect cameras: neutron radiation and gamma radiation. Appropriate underwater cameras and air cameras for nuclear use must resist the radiation.

Neutron radiation

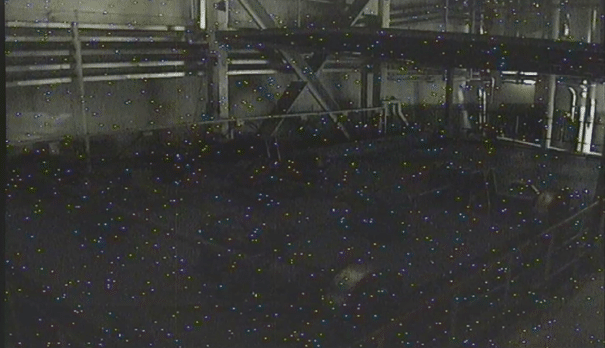

In a standard nuclear reactor, Uranium-235 is split into two or more isotopes and neutrons are released. Some of these neutrons are used to make more uranium to split, but some neutrons inevitably leave the nuclear core. If these neutrons are not shielded by water, concrete, or any other protective material, a nearby camera installation is going to be damaged. Neutron damage in a camera is normally seen as steady dots on the screen connected to the camera.

Gamma radiation

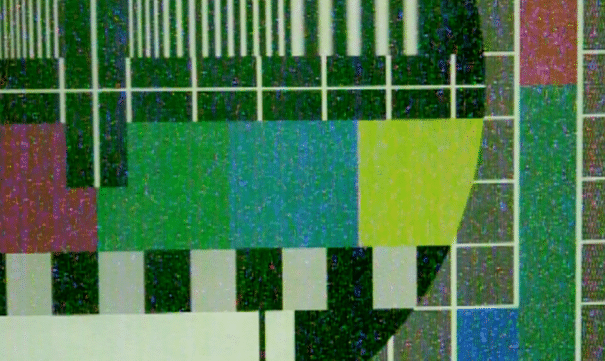

When Uranium-235 is split, gamma radiation is also produced. This type of radiation continues to be produced when the residual isotopes are split. Gamma radiation thus not only exists during the operation of nuclear plants, but also in nuclear plants during an outage, as well as plants handling spent nuclear fuel and nuclear waste. Gamma radiation from the isotope Cobolt-60 is especially common and harmful due to its high energy level. Therefore, in test laboratories Cobolt-60 is normally the radiation source. Damages from gamma radiation can be seen as colorful dots in motion on the screen.

What is the radiation level?

There are a number of different units to measure radiation. When gamma radiation affects human beings, the unit sievert (Sv), is used. People entering a nuclear plant generally must put on a dosimeter. This device displays the total amount of Sv a person has received during the stay inside the plant. Since amounts are low, the dosimeter displays microsieverts (μSv).

The momentaneous dose that is received is measured by sievert per hour (Sv/hr). This is also called the dose rate. The accumulated dose, also called the total dose, is measured by Sv. When gamma radiation affects equipment, like cameras, the unit grey (Gy) is used. One Gy equals one Sv in this case. Throughout the nuclear industry, the unit rad(s), is also common. Conversion between the two units is easy since 1 Gy equals 100 rad/rads.

| Dose rate | 1 Sv/hr | 1 Gy/hr | 100 rad/hr |

| Total dose | 1 Sv | 1 Gy | 100 rad |

Detailed measuring of neutron radiation levels is not common in the nuclear industry. Generally, levels are considered high, medium, or low.

Is a standard camera enough or is a radiation tolerant camera necessary?

A standard camera with no radiation protection can only receive a small amount of radiation before the image quality is so poor that no meaningful image can be seen. In a nuclear environment, such a camera would fail after short usage. However, some users prefer to use these non-radiation tolerant cameras for radiation environments as well and replace them with new ones after failure. That can be an option for short operations but can become costly with long-term use. For long-term use, users should opt for radiation tolerant cameras which resist between 10 and 10 000 times more radiation.

How will the camera be protected from radiation?

Shielding

Negative impacts from radiation can be prevented by shielding. Different materials have different shielding capabilities. Water has beneficial characteristics and approximately 0.1 m (4”) of clean water halves the intensity of gamma radiation. Air is not as good; gamma radiation can travel around 1 m (40”) in air before its intensity is halved. Higher density materials are in general better to hinder gamma radiation to pass. Lead is one such high-density material that is often used for shielding. Tungsten has even higher density and thus better shielding, however, it´s considerably more expensive than lead.

In contrast to gamma radiation, neutron radiation is shielded by lighter materials. As detailed measuring of neutron radiation levels is not common in the nuclear industry, there is also no common knowledge on how much neutron radiation is reduced in different thicknesses of different materials.

The easiest way of achieving a radiation tolerant camera is to physically shield a standard camera. As described above, heavy materials such as lead and tungsten are often used as shielding materials to prevent the camera from swelling too much. As a rule of thumb, each centimeter of lead outside a camera halves the gamma radiation level inside.

Protecting cameras solely with materials makes them big and heavy. To produce radiation tolerant cameras that are more user-friendly, smarter design is necessary. For this reason, mirrors can be used in high-radiation applications. Core technology like radiation tolerant image sensors and other electronic components is also used. The use of radiation tolerant camera electronics is much more efficient than the physical shielding of a standard camera.

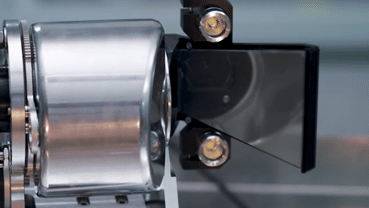

Mirror designed cameras

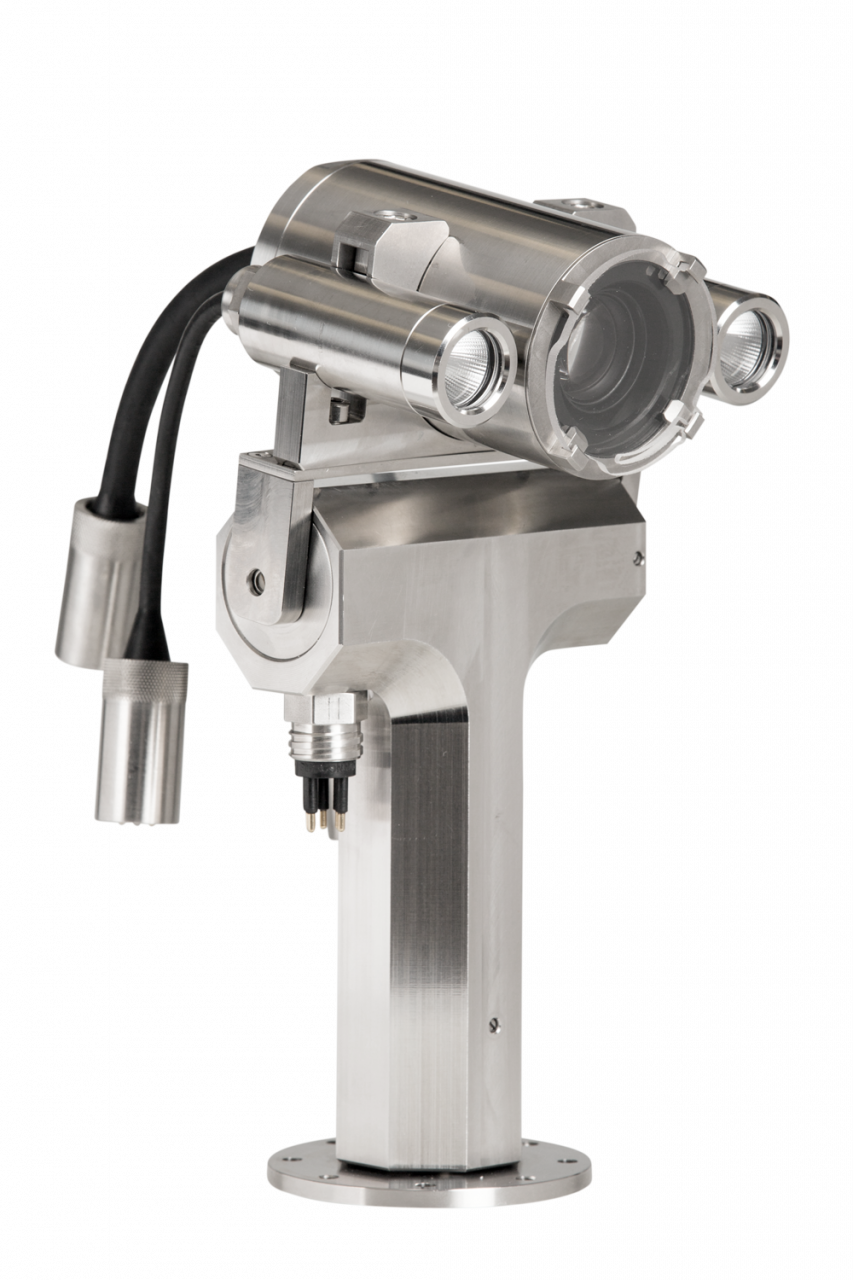

One way of making cameras last longer when looking at an object that emits radiation is to have the camera look at the object using a mirror. This design can be seen on Ahlberg Cameras’ PTZ620 radiation tolerant camera. This way, the sensitive camera sensor, also called the camera module, is not directly exposed to the radiation source.

Another camera using the mirror design is Ahlberg Cameras’ Z160 radiation tolerant camera. In addition to the mirror, the camera sensor is protected by a few centimeters of shielding material. With this protection, the nuclear camera can resist dose rates of up to 10 000 Gy/h and be suitable for underwater nuclear fuel inspection at a distance of 50-70 cm (20-28”).

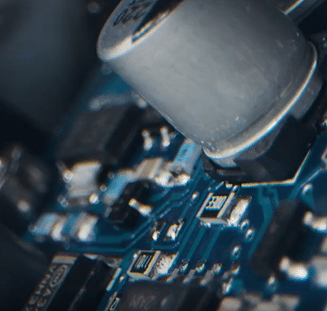

Radiation tolerant sensors

Manufacturers of radiation tolerant cameras, like Ahlberg Cameras, are constantly trying to make the parts inside the camera, primarily the camera sensor, more tolerant to radiation. This is done by advanced design of electronical components and builds on years of continuous improvements.

Until now, such design has resulted in camera sensors withstanding a total dose of around 1 000 Gy. Lately, development has made a leap and it is now possible to produce sensors that resist a total dose of almost 50 000 Gy. In the second half of 2020, Ahlberg Cameras released the Mini-Rad 30 HD, based on this new sensor technology.

With a combination of a radiation tolerant sensor, mirror, and shielding, it is now possible to get a HD color camera for use in high-radiation areas where previously only tube cameras could operate. Tube cameras are built upon a technology that is less sensitive to radiation; however, they have the disadvantage of only providing a black/white image.

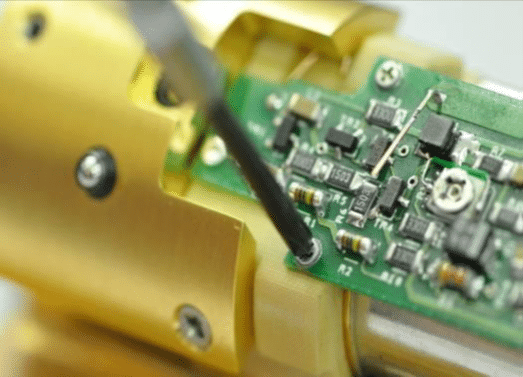

Other parts of the camera

The camera sensor is the most sensitive part to nuclear radiation inside the camera. The lens can also be a sensitive part due to the fact that radiation can discolor the lens material. Lenses are typically made of glass, but they can also be made of plastic, such as acrylic or polycarbonate. The drawback of plastic and standard glass materials is that if they are exposed to high levels of radiation, the transparent material gradually gets yellow and then brown.

In high-radiation cameras, which, as the name suggests, are exposed to very high levels of radiation, special non-browning glass is used. This is made of synthetic quartz glass or other radiation tolerant transparent material. These are more expensive than the plastic alternatives and more difficult to elaborate. Other parts inside the camera, such as motors, cabling, and O-rings can be selected to be negligibly impacted by radiation.

Is the camera for use in air or underwater?

Underwater nuclear cameras are pressure tested for use down to 20-50 m (65-165 ft) under water. Few pools in nuclear sites are deeper than 35 m (115 ft). Cameras made for air installation are not waterproof but provide generally IP65 or IP67, tolerant of water jets or extremely humid environments.

As mentioned earlier, neutrons are only spread during the nuclear reaction process, but not after a reactor is shut down. In contrast, gamma radiation is also emitted after shut-down because the fission continues in the residual isotopes. Underwater cameras are only used in reactor pools when the reactor is shut down or in pools where neutrons from an ongoing nuclear reaction process cannot reach. Hence, underwater cameras do not need any shielding against neutrons, only protection against gamma radiation.

In contrast to the underwater cameras, cameras placed in air may need neutron protection. That only goes for cameras placed inside the containment in operating power plants. Air-placed cameras outside the containment only need protection against gamma radiation.

Most underwater cameras in nuclear applications are not used in water temperatures above 40-50 degrees Celsius (104-122 degrees Fahrenheit) and no cooling of the camera’s internal components is necessary. The heat produced in the internal parts is led to the camera housing and is then transferred to the water. Cameras placed in air can however experience higher air temperatures. And transferal of heat from the camera housing to air is not as effective as it is to water. Since the temperature inside the containment is normally 50-60 degrees Celsius (122-140 degrees Fahrenheit) during operation, a camera in this environment needs cooling of its sensitive sensor. Cameras inside the containment that must continue operating during a LOCA scenario, when temperatures inside the containment can reach up to 90 degrees Celsius (194 degrees Fahrenheit), need even more cooling.

Cooling can be achieved in different ways. Natural convection, improved by cooling fins, is enough at surrounding air temperatures of 40-45 degrees Celsius (104-113 degrees Fahrenheit).

At operational temperatures of 50-55 degrees Celsius (122-131 degrees Fahrenheit), forced cooling by a fan is necessary. For temperatures of 60-90 degrees Celsius (140-194 degrees Fahrenheit) the fan must be complimented by internal cooling that actively pulls the heat from the inner part of the camera, where the sensor is situated, to the rear, where the fan is situated. Internal cooling can be achieved by custom-designed cooling elements of various sizes.

Cameras placed in air are generally known as CCTV cameras. The term stems from the Closed Circuit Television systems that have been found outside the nuclear industry for many years and are seen more and more in public places. Also, in a nuclear plant, the CCTV cameras are interconnected into a system which ultimately is controlled from the central control room.

How accessible is the camera, how often is it possible to perform service?

Most underwater cameras that are used for general work in reactor and fuel pools can be serviced at any time. Underwater cameras that perform a critical task, such as during an outage, must perform well throughout completion of the task. CCTV cameras placed inside the containment or in rooms that are not accessible during nuclear operation can only be serviced during an outage which can be once every 12, 18, or 24 months.

Tube cameras must be calibrated on a regular basis. The tube itself seldom requires exchange due to its high radiation resistance.

Charged coupled device (CCD) and complementary metal oxide semiconductor (CMOS) color cameras do not need any continuous calibration. However, the camera sensor needs to be replaced once it reaches end of life. Along its lifetime, the camera operator is going to encounter degradations that gradually deteriorate the image. Once the sensor has been replaced, the camera image is like new again.

The camera sensor should be seen as a consumable. Since the overall radiation tolerance of the camera is usually reflected in its price, a user must consider how often the color camera can be serviced. There is a tradeoff between overall radiation tolerance of the camera and acceptable service intervals. If the sensor must be exchanged too frequently, the shielding of the camera is not good enough. On the other hand, if the sensor never has to be replaced, a camera with too much shielding was chosen. This is not the most economical solution and it also makes the camera unnecessarily clumsy.

What is the camera going to look at, where is it going to be fixated?

Cameras are connected to a camera control unit via a camera cable. The control unit powers and controls the camera and it is placed away from the radiation source. The camera must naturally be placed near the object(s) it looks at. Whereas detailed inspection of nuclear fuel and reactor materials normally must take place at a distance of 30-100 cm (10-40”), the camera can, for general tasks, be placed further away from the object, between 150-200 cm (4-6 ft).

A good rule of thumb is to not place the camera closer to the radiation source than necessary, and instead, let the zoom provide a good image. Color cameras typically provide 10 times optical zoom; additional digital zoom is normally available. Tube cameras provide less zoom and are used closer to the object.

CCTV cameras that are placed in rooms to survey several interesting objects are naturally placed further away, in some cases up to 15-20 m (50-65 ft) away. In these cases, a capable zoom feature is of great benefit.

In applications where one single object is to be monitored and the camera is fastened to a bracket, frame or similar, a fixed focus camera is a good solution. With a known distance to the object, a radiation resistant camera supplier can provide a suitable lens that captures the complete object, while the user only needs to set the focus.

If the user wants a camera solution for use in many different applications, a pan-and-tilt feature is recommended. The pan-and-tilt feature, which enables the camera to turn up, down, left, and right, can be executed by an external unit that moves the complete camera, or it can be performed internally by solely moving the camera head. Cameras with internal movement are called PTZ cameras (pan, tilt, zoom) and are widely used in the nuclear industry thanks to their flexibility. The Hi-Rad (XS, S, L) from Ahlberg Cameras are general purpose cameras used in many applications at nuclear sites.

There is a wide variety of options for the mounting of cameras, all depending on application and ambient conditions. Cameras can be fixated to accessories such as brackets, frames, or tools of numerous designs. They can be fastened to a pole or simply hang down from its cable.

What resolution is required?

When describing the image quality of SD (standard definition) color cameras, the unit, TV-lines, is used. SD cameras have been around for a long time and typically render 400-600 TV-lines for lower quality cameras and about 700 TV-lines for higher quality products. The resolution of tube cameras is also presented in TV-lines. It can be up to 600-700 TV-lines in the center of the image but fall to 400-500 in the image periphery. The resolution in modern color HD cameras varies widely; within the nuclear industry, mostly 720p and 1080p cameras are found.

The difference in image quality between traditional SD cameras, tube cameras, and modern HD cameras is evident when looking at details, for example, fuel inspection and material inspection in nuclear reactors.

An advantage of the HD camera in comparison to a lower resolution camera is the ability to perform inspections at a distance. As recommended earlier, it´s better to stay further away from the radiation-emitting object you want to look at and zoom in, than to stay close to the object. This way the camera is exposed to less radiation while providing a clear image and having a longer life.

The cleanliness of the water in underwater applications can place a limit as to how far away the camera can be placed. Another bothersome fact when inspecting warm objects, such as used nuclear fuel, is the appearance of heatwaves in the water. Seen from above, heatwaves create a greater disturbance than when looking from the side. Fortunately, the disturbance can be reduced by using thermal removal software.

If you would like to learn more about radiation tolerant cameras you can book an online demo. If you would like to leave questions or comments regarding this text, please contact us at sales@ahlbergcameras.com.